Industrial Robotics: How bad PR can stunt the growth of an advanced industry

By James Fahy, Account Director in Energy

Robots have been a feature of industry for years, but it took just seven years for the average robot density in the world’s factories to double. In 2016 you could expect to encounter 74 units per 10,000 employees, and by 2023 that figure sat at 162. In the world’s leading region for robots, Europe claims a density of 219 units per 10,000 employees.

What has changed in robotics since 2016 to cause this dramatic shift? And what has been the impact on sectors such as manufacturing and retail?

Digital steroids

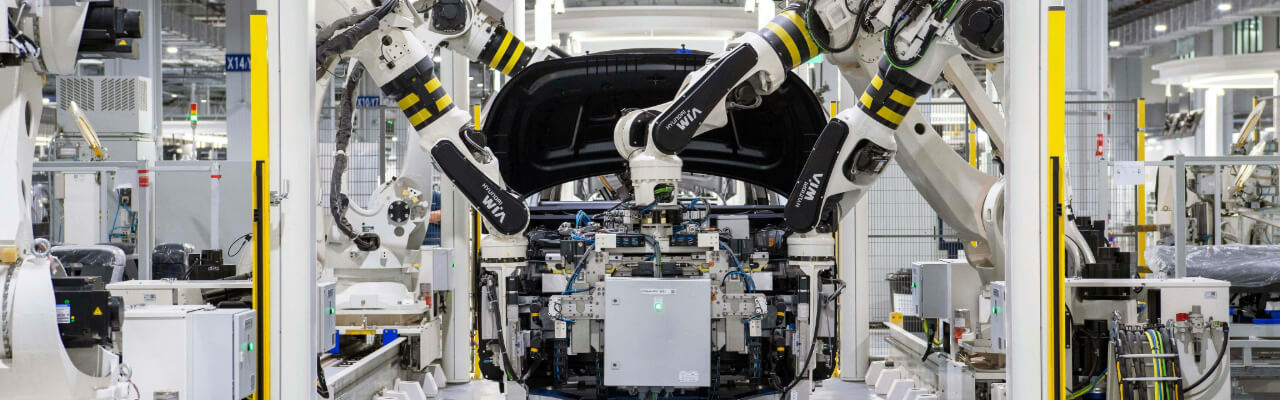

Like a number of industries, robotics has undergone rapid advancements in technology that have supercharged the capabilities of existing forms of machines and spurred the growth in their demand. Take robot arms, which were already in use at scale in factories by the 1960s to perform repetitive motions in production lines. Their uses may not be so different these days, but the efficiency at which they operate is a far cry from before. Nikon recently released a new vision system for robotic arms that has a processing speed of 250 frames per second; four times faster than a human.

Comparison with humans is a helpful way to understand the capabilities of robots, but it is also a source of anxiety. That has increased with the move from limb-only functions to the full-bodied variety; Telsa expects to have its humanoid robot Optimus ready for use in its factories by the end of 2025.

For the companies producing robots, their parts and the required software, they must recognize this rapid change can be unsettling. The race to build bigger and better robots has given rise to fears over job losses, which is being immortalized in dramatic newspaper headlines and prompting farfetched comparisons with science fiction films.

Terminating myths

The reality of robots for their human colleagues is usually much more benign; a reduced risk of injury and time freed up to handle the more complex and creative tasks. When Amazon announced increased automation at its Louisiana fulfilment center in 2024, it laid out the benefits to its employees as well as its customers. The new systems allow staff to work safely and securely in the power zone between mid-thigh and mid-chest, and these more advanced fulfilment centers create 30% more jobs in higher paid reliability, maintenance and engineering roles.

Without this kind of proactive communication to support change, companies risk a vacuum emerging over industrial robotics that buries the positives of increased automation and alienates their workers. That acts a dead weight on efforts for those businesses to bring in skilled staff and raise revenues.

For a company to make their reforms more compelling, they need to come up with creative and topical story ideas that demonstrate the power of robotics to enhance the human touch rather than replace it. Those stories must be adjusted according to internal and external communications channels, so they are tailored to each audience.

The good news is they don’t have to do all that alone. The Energy & Industrials team at Aspectus Group is made up of sector specialists who understand the industry landscape and know the right media inside and out. We are in an almost unparalleled position to advise, and act on behalf of, businesses in the robotics industry and help them meet their business objectives.

Key takeaways:

- Advanced technology is supercharging the industrial robotics industry

- That rise is coupled with increasingly negative perceptions, which will hamper revenue-raising activity

- Communications experts should be consulted to support with brand building activities and positive storytelling that will mitigate reputational risks and pave a smoother path to revenue growth

The author of this blog James Fahy, Account Director at Aspectus Group, welcomes comments or questions on email at james.fahy@aspectusgroup.com or by phone on +44 7722 478906